How is the tear-off force of a magnet measured?

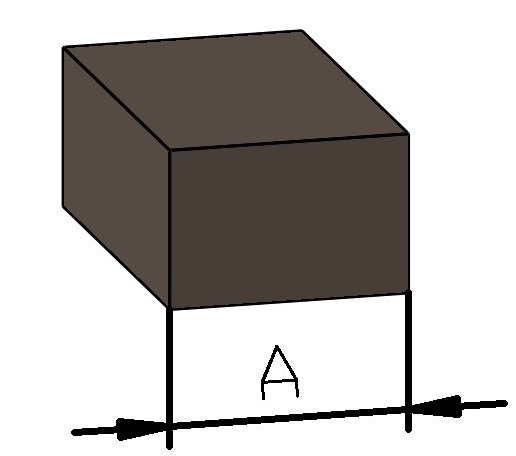

The tear-off force is the force required to pull a magnet away from a steel (magnetic) plate under the following conditions:

• The plate must be made of pure steel and be at least 10 mm thick.

• The entire surface area of the magnet touches the given object, so the magnet must be in perfect contact with the plate.

• The magnet is pulled perpendicular to the plate.

What reduces the magnetic force of the magnet?

• The entire surface of the magnet does not touch the object because the given object’s surface is uneven.

• The magnet can slide sideways if it is not pulled perpendicular to the surface, so it will tear off much more easily.

• The magnetic object is not made of pure (magnetic) steel, there is probably a coating of paint, a layer of rubber or plastic or other material on the surface that increases the distance between the magnet and metal plate.

• The magnet does not touch the object, the greater the distance between the magnet and metal plate, the smaller the magnetic force.

• The object is corroded.

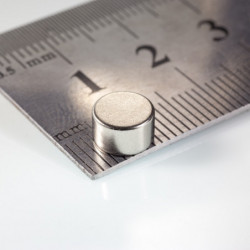

Magnet Surface Finish

Nickel is applied to the magnet surface to protect the magnet from corrosion. Caution, if used outdoors for long periods of time or if the finish is damaged, the magnet will begin to oxidise.

Neodymium magnets are very susceptible to corrosion, so they are usually coated with nickel (10-20 µm), zinc (5-10 µm), gold (5-10 µm), epoxy resin (20-30 µm) or passivated (0 µm). A copper layer is usually used as an intermediate layer under the final surface finish.

Neodymium Magnet vs. Ferrite Magnet

Advantages (ferrite magnet vs. neodymium magnet)

- The most powerful neodymium magnets can lift up to a thousand times their weight

- The minimum size of a neodymium magnet outperforms a ferrite magnet by several times

- Neodymium magnets are made by cutting, so almost "any" shape can be custom made. To produce ferrite magnets, a press mould is usually required. For some dimensions, cutting can also be chosen, but only for bigger quantities

Disadvantages (ferrite magnet vs. neodymium magnet)

- Neodymium magnets are more expensive

- Neodymium magnets are prone to corrosion

- Ferrite magnets all have the same temperature resistance, so there is no need to choose different types of materials as with neodymium magnets, whose temperature resistance is determined by the type of material

Neodymium magnets are produced by sintering and their anisotropy (direction of magnetisation) is usually already preset during the production of blanks, which are then cut to specific final dimensions. Therefore, except in exceptional cases, it is not possible to select the type of magnetisation after the final dimension of the neodymium magnet is completed. In contrast, ferrite magnets, their isotropic version, can be magnetised in different variations and directions using the selected magnetising agent. Ferrite anisotropic magnets also have the magnetisation direction set during production, because they are wet-moulded, i.e. in a pre-set magnetisation direction.

FERRITE VS. NEODYMIUM MAGNETS: Powerful neodymium magnets can cause a change in the direction of magnetisation or complete demagnetisation (loss of magnetic force) in ferrite magnets. Therefore, do not put neodymium magnets and ferrite magnets close to each other or together. Store them at least 10 cm apart.

For more information, please proceed to the customer FAQ or contact us.

ROHS statement

The reported tear force values for some products were measured under ideal conditions given by the test environment. However, these values may vary depending on the specific type of environment where, for example, operating conditions and subsequent wear may affect the effectiveness of the product. However, measurements have not been made for all products and in such cases are only an estimate or internal auxiliary calculation by the vendor. The values quoted are therefore to be considered as indicative and the Seller declares that they are not a description of the goods in terms of the agreed characteristics in the sales contract on the basis of Article 6(a) of Directive (EU) 2019/771 of the European Parliament and of the Council of 20 May 2019 on certain aspects of contracts for the sale of goods, amending Regulation (EU) 2017/2394 and Directive 2009/22/EC and repealing Directive 1999/44/EC. In order to determine the exact value of the tear force in a specific case, it is necessary to carry out the actual measurement. In case the detected values of the breakaway force are not sufficient for you, as they do not correspond to the stated values, you can take advantage of the guaranteed return option within 30 days under the conditions stated here: https://magsy.shop/goods-returning/ and purchase a stronger magnet. These 30 days are just for testing the goods, after which the seller can refuse the return.

WARNING: Magnets are intended for use in an indoor, dry environment only. Do not use magnets in shower enclosures or near bathtubs, sinks, wash basins or anywhere moisture may affect them. Contact us if you need magnets for wet environments.

Magnetic cubes

Magnetic cubes Small magnets

Small magnets Bar magnets

Bar magnets Large magnets

Large magnets Flat magnets

Flat magnets Circular magnets

Circular magnets Eye magnet

Eye magnet Ferrite magnets, cylinders, magnetized in parallel to the axis

Ferrite magnets, cylinders, magnetized in parallel to the axis Ferrite magnets, prisms, magnetized perpendicularly to the surface

Ferrite magnets, prisms, magnetized perpendicularly to the surface Ferrite magnets, rings, magnetized in parallel to the axis

Ferrite magnets, rings, magnetized in parallel to the axis Ferrite magnets, cylindres, magnetized with multiple poles

Ferrite magnets, cylindres, magnetized with multiple poles Color ferrite magnets

Color ferrite magnets Cheap magnets

Cheap magnets SmCo magnets, cylinders, magnetized in parallel to the axis

SmCo magnets, cylinders, magnetized in parallel to the axis SmCo magnets, prisms, magnetized perpendicularly to the surface

SmCo magnets, prisms, magnetized perpendicularly to the surface SmCo magnets, rings, magnetized in parallel to the axis

SmCo magnets, rings, magnetized in parallel to the axis Magnetic letters

Magnetic letters Coloured magnets

Coloured magnets Color conical rare-earth magnets

Color conical rare-earth magnets Color magnetic pegs

Color magnetic pegs Magnets in the plastics cases

Magnets in the plastics cases Magnets in the metal cases

Magnets in the metal cases Magnets in the silicone cases

Magnets in the silicone cases Strong office magnet, neodymium

Strong office magnet, neodymium Magnetic arrows

Magnetic arrows Magnetic numbers

Magnetic numbers Magnetic smileys

Magnetic smileys Magnets for business cards

Magnets for business cards Self-adhesive magnet – a counterpart

Self-adhesive magnet – a counterpart Counterpart for the magnet with a screw hole

Counterpart for the magnet with a screw hole Attachment sets

Attachment sets Self-adhesive labels to be used with magnets

Self-adhesive labels to be used with magnets Sensor foils

Sensor foils Neodymium self-sticking magnets, prisms, magnetized perpendicularly to the surface

Neodymium self-sticking magnets, prisms, magnetized perpendicularly to the surface Cheap magnets

Cheap magnets Magnetic attachment sets

Magnetic attachment sets Neodymium magnets, prisms with holes, magnetized perpendicularly to the surface

Neodymium magnets, prisms with holes, magnetized perpendicularly to the surface Neodymium magnets, rings, magnetized in parallel to the axis

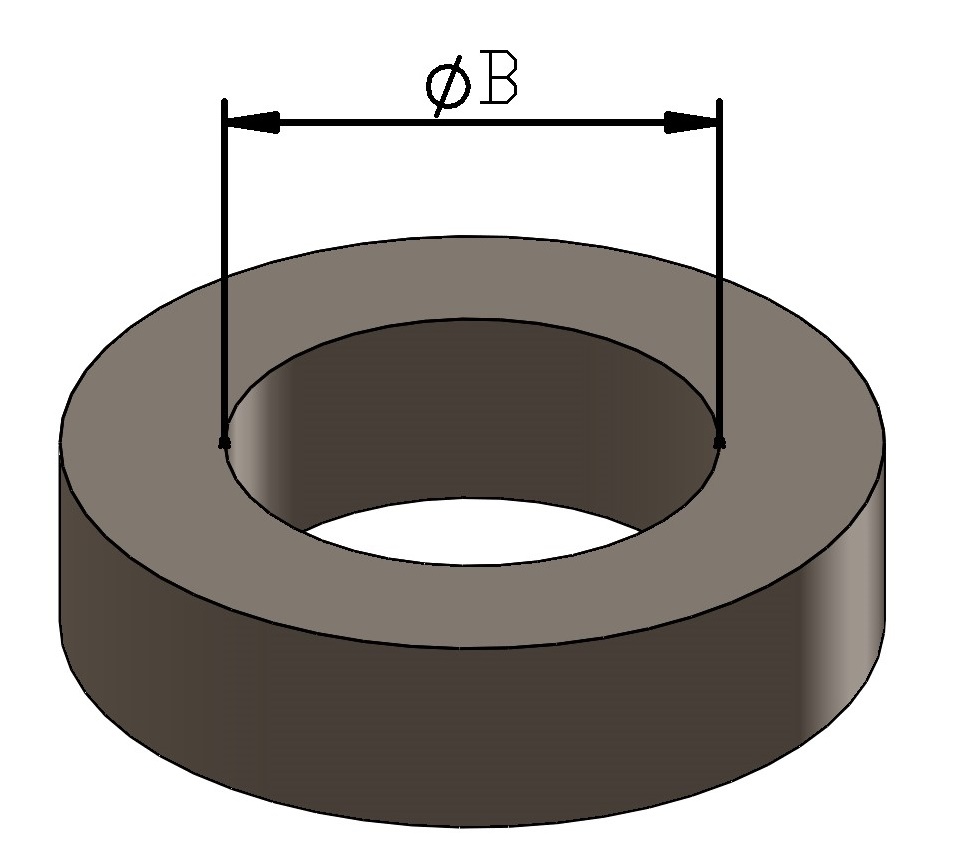

Neodymium magnets, rings, magnetized in parallel to the axis Neodymium magnets, cylinders with screw hole, magnetized in parallel to the axis

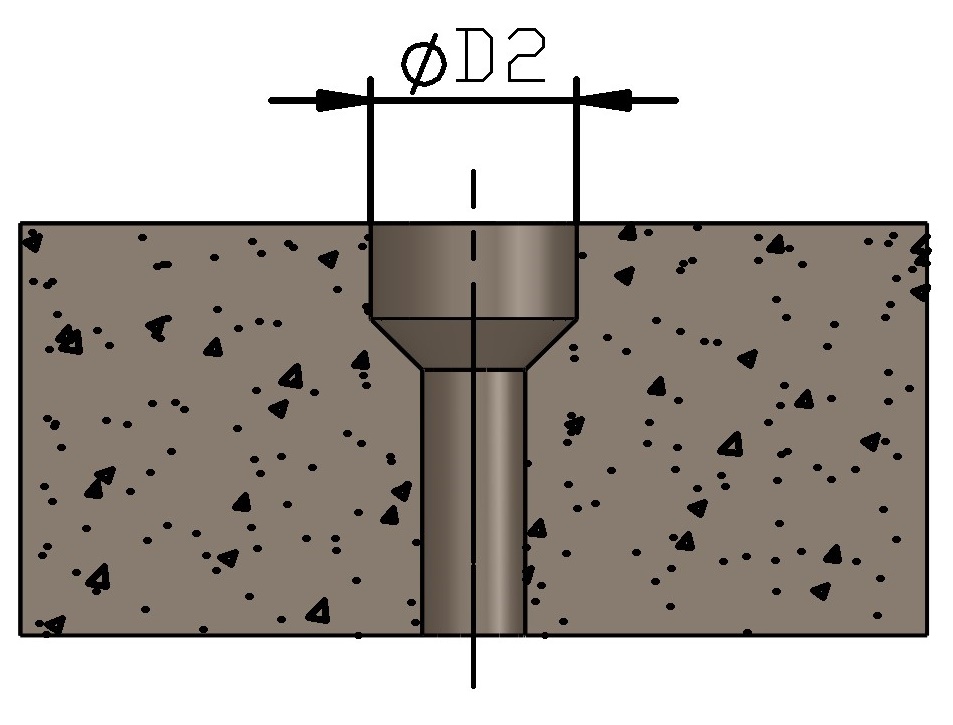

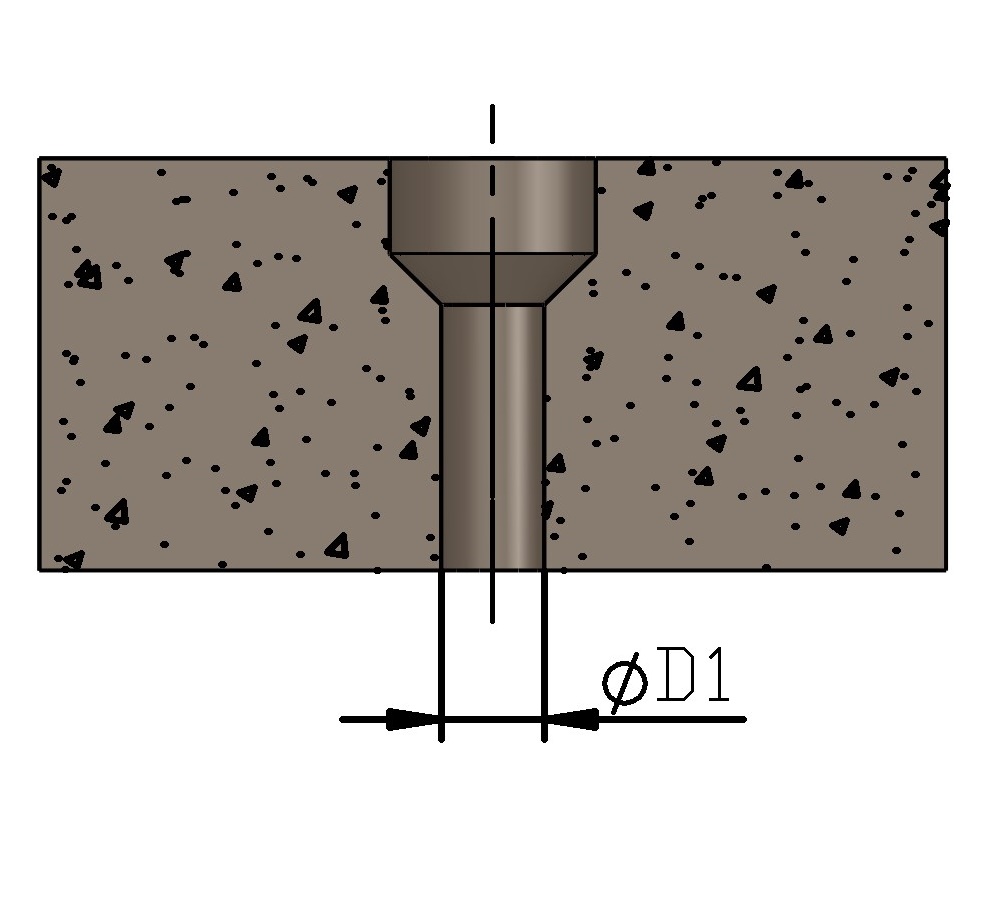

Neodymium magnets, cylinders with screw hole, magnetized in parallel to the axis Neodymium magnets, cylinders, magnetized perpendicularly to the axis

Neodymium magnets, cylinders, magnetized perpendicularly to the axis Neodymium magnets, cylinders, magnetized in parallel to the axis

Neodymium magnets, cylinders, magnetized in parallel to the axis Atypical neodymium magnets

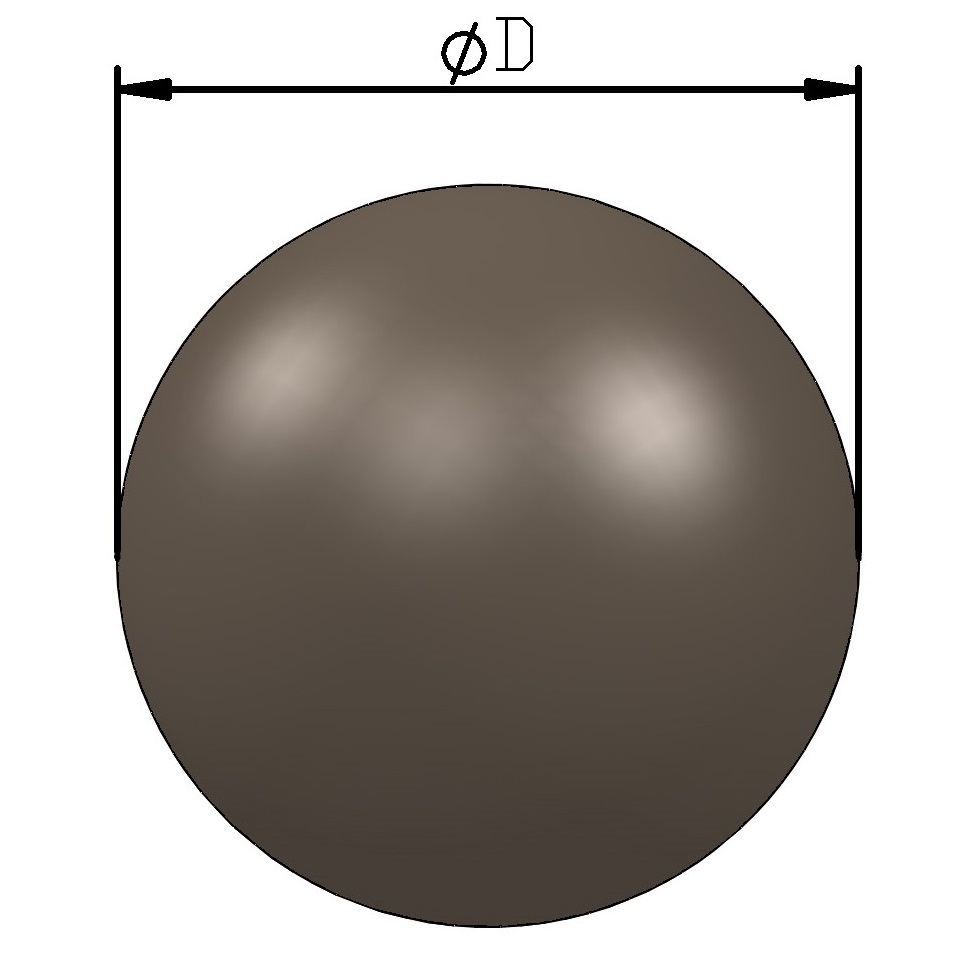

Atypical neodymium magnets Magnetic balls

Magnetic balls Neodymium magnets, segments, magnetized perpendicularly to the surface

Neodymium magnets, segments, magnetized perpendicularly to the surface Neodymium magnets, rings, magnetized perpendicularly to the axis

Neodymium magnets, rings, magnetized perpendicularly to the axis Neodymium magnets, prisms, magnetized perpendicularly to the surface

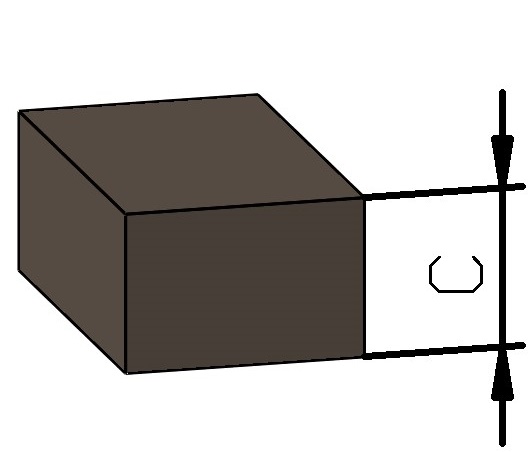

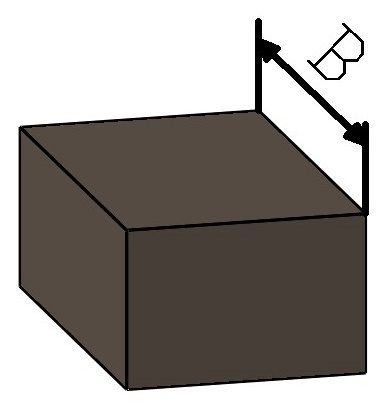

Neodymium magnets, prisms, magnetized perpendicularly to the surface Neodymium magnets, prisms, magnetized in the longitudinal direction

Neodymium magnets, prisms, magnetized in the longitudinal direction Board magnets

Board magnets Baby fridge magnets

Baby fridge magnets Wooden magnets

Wooden magnets Animal magnets

Animal magnets Fridge magnets

Fridge magnets Photo magnets

Photo magnets Magnetic separators for kaolin

Magnetic separators for kaolin Magnetic pellet separators

Magnetic pellet separators Magnetic separators for wood chips

Magnetic separators for wood chips Magnetic separators on soot

Magnetic separators on soot Magnetic flour separators

Magnetic flour separators Magnetic separators for plastic granules

Magnetic separators for plastic granules Magnetic sugar crystal separators

Magnetic sugar crystal separators Magnetic separators for powdered sugar

Magnetic separators for powdered sugar Magnetic separators for ceramic material

Magnetic separators for ceramic material Magnetic separators for rinsing baths

Magnetic separators for rinsing baths Magnetic separators for cooling oil

Magnetic separators for cooling oil Magnetic separators for sugar juice

Magnetic separators for sugar juice Magnetic glaze separators

Magnetic glaze separators Magnetic pate separators

Magnetic pate separators Magnetic ketchup separators

Magnetic ketchup separators Magnetic yogurt separators

Magnetic yogurt separators Magnetic oil separators

Magnetic oil separators Magnetic separators for cooling emulsion

Magnetic separators for cooling emulsion Magnetic grids, finger magnets

Magnetic grids, finger magnets Magnets for injection moulding machine hoppers

Magnets for injection moulding machine hoppers Magnetic rods

Magnetic rods Separation vessels

Separation vessels Rotational magnetic separators

Rotational magnetic separators Plate magnetic separator

Plate magnetic separator Telescopic magnetic separators - with automatic cleaning

Telescopic magnetic separators - with automatic cleaning Telescopic magnetic separators - with manual cleaning

Telescopic magnetic separators - with manual cleaning Magnetic testing rods

Magnetic testing rods Magnetic drums

Magnetic drums Flow magnetic separators

Flow magnetic separators Magnetic plates

Magnetic plates Yeckel 50x50x3 mm

Yeckel 50x50x3 mm Yeckel 25x15x1,5 mm

Yeckel 25x15x1,5 mm Yeckel 25x25x2 mm

Yeckel 25x25x2 mm Yeckel 30x20x2 mm

Yeckel 30x20x2 mm Yeckel 30x30x3 mm

Yeckel 30x30x3 mm Yeckel 30x30x2 mm

Yeckel 30x30x2 mm Yeckel 40x40x2 mm

Yeckel 40x40x2 mm Yeckel 50x20x2 mm

Yeckel 50x20x2 mm Yeckel 60x60x4 mm

Yeckel 60x60x4 mm Yeckel 70x70x2 mm

Yeckel 70x70x2 mm Yeckel 60x40x4 mm

Yeckel 60x40x4 mm Yeckel 60x60x2 mm

Yeckel 60x60x2 mm Yeckel 100x100x3 mm

Yeckel 100x100x3 mm Yeckel 120x80x3 mm

Yeckel 120x80x3 mm Yeckel 200x100x3 mm

Yeckel 200x100x3 mm Yeckel 20x20x2 mm

Yeckel 20x20x2 mm Stainless steel L profile 40x40x4 mm

Stainless steel L profile 40x40x4 mm Stainless steel L profile 30x30x3 mm

Stainless steel L profile 30x30x3 mm Stainless steel L profile 25x25x3 mm

Stainless steel L profile 25x25x3 mm Stainless steel L profile 20x20x3 mm

Stainless steel L profile 20x20x3 mm Stainless steel L profile 20x10x3 mm

Stainless steel L profile 20x10x3 mm Stainless steel rods 20 mm

Stainless steel rods 20 mm Stainless steel rods 25 mm

Stainless steel rods 25 mm Stainless steel rods 28 mm

Stainless steel rods 28 mm Stainless steel rods 30 mm

Stainless steel rods 30 mm Stainless steel rods 3 mm

Stainless steel rods 3 mm Stainless steel rods 12 mm

Stainless steel rods 12 mm Stainless steel rods 9 mm

Stainless steel rods 9 mm Stainless steel rods 10 mm

Stainless steel rods 10 mm Stainless steel rods 8 mm

Stainless steel rods 8 mm Stainless steel rods 6 mm

Stainless steel rods 6 mm Stainless steel rods 5 mm

Stainless steel rods 5 mm Stainless steel rods 4 mm

Stainless steel rods 4 mm Stainless steel rods 18 mm

Stainless steel rods 18 mm Stainless steel rods 100 mm

Stainless steel rods 100 mm Stainless steel rods 14 mm

Stainless steel rods 14 mm Stainless steel rods 32 mm

Stainless steel rods 32 mm Stainless steel rods 35 mm

Stainless steel rods 35 mm Stainless steel rods 36 mm

Stainless steel rods 36 mm Stainless steel rods 40 mm

Stainless steel rods 40 mm Stainless steel rods 45 mm

Stainless steel rods 45 mm Stainless steel rods 50 mm

Stainless steel rods 50 mm Stainless steel rods 55 mm

Stainless steel rods 55 mm Stainless steel rods 60 mm

Stainless steel rods 60 mm Stainless steel rods 70 mm

Stainless steel rods 70 mm Brushed pipes

Brushed pipes Welded pipes

Welded pipes Seamless pipes

Seamless pipes